Rotary Die Cutting

From die-cut adhesives and decals, to graphics for the automotive industry and die-cut adhesive backings for the telecommunications market, Trient Technologies, is a leader in the converting of rotary die-cut parts into precision OEM applications and after-market products. Trient Technologies is a sister company of Tekra and operates independently.

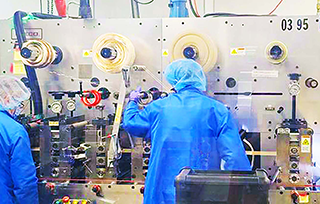

Clean Room Rotary Die Cutting and Assembly

Trient partners with automotive and medical OEMs to provide clean room manufacturing in our state-of-the-art clean room facility.

Contract Manufacturing and Assembly

Trient specializes in contract manufacturing and assembly. In many cases, the contract manufacturing process begins with the converting of large rolls of both graphic and functional parts via roll-to-roll slitting, die cutting, and laminating. Products are prepared for industrial OEM, aftermarket, or retail applications. Products can then be introduced to primary or intermediate packaging, and prepared to ship. Trient’s unique ability to fulfill every function of the supply-chain results in faster turn-time, reduced cost, and the elimination of excess overhead.

Industrial Converting

At Trient Technologies, we specialize in converting rolled and/or thin raw materials into OEM and aftermarket parts and products, including tapes, adhesives, decorative films, and graphics. This unique niche allows us to service a wide variety of markets, from the automotive industry to telecommunications to medical. Trient’s services and capabilities extend far beyond the manufacturing process. We leverage custom state-of-the-art equipment and production processes to provide companies with a total supply-chain resource. From the initial product development to the end fulfillment of OEM and retail orders, Trient can offer a complete supply-chain solution.

Packaging, Fulfillment & Distribution

Trient's industrial converting capabilities only represent one facet of the entire product life cycle. From initial product engineering through order fulfillment and distribution, Trient can truly be your one-stop shop. This turnkey approach extends to even the packaging and warehousing of products. Through a JIT/Kan Ban inventory management system, we can provide faster turn time, reduce obsolescence, lower overall cost and eliminate excess overhead.

Prototyping

Want to make sure that your die-cut tooling will work before you invest the money to build it? Our prototyping services can save you money and time and provide peace of mind that your solution will be effective.

Industrial Assembly, Warehousing & Distribution

Offering our clients numerous services in one location including industrial assembly, warehousing and distribution allows Trient customers a complete business solution. Save money and find peace of mind by utilizing the reliable industrial solutions at Trient Technologies.